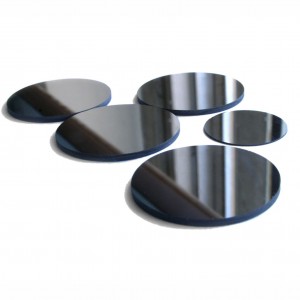

Polycrystalline Cubic Boron Nitride (PCBN) yeMachining Applications

PCBN macomposites anogadzirwa ne sintering micron CBN poda neakasiyana ceramic, kuitira kuti igadzire zvakanyanya kuomarara uye zvakagadzikana zvekushandisa zvekushandisa Zvizhinji zvePCBN zvinhu zvakabatanidzwa zvakabatanidzwa kune simende ye carbide substrate.CBN ndiyo yechipiri yakaomesesa zvinhu inozivikanwa mushure mekugadzira dhaimani, asi ine yakakwira kupisa uye makemikari kuramba zvivakwa.Inonyanya kushandiswa mukucheka nekugadziriswa kwekuoma kwepamusoro kana kuoma kugadzira zvinhu zvinosanganisira simbi yakaoma, grey uye yakakwirira simba rakakandwa simbi, high speed simbi, cast iron quench alloy, sintering metal materials, nezvimwewo.

| Kodhi # | Diameter (mm) | Dhaimondi (mm) | Urefu(mm) | Abrasive ratio | Feature | Application |

| HC1303 | 13.5 | 0.8-1.0 | 3.2 | > 10000 |

CBN layer uye Wc-co substrate Yakakwira CBN zvemukati 2. High kupfeka resistance 3. Simba rakanaka rekuputika 4.Kugadzikana kwemakemikari akanaka | 1. Precise dimension2.Gray cast Iron3.Powered Metal4.Kudzivisa kupisa 5. Kudzima alloy 6. Zvishandiso simbi & kufa simbi |

| HCF1304 | 13.5 | 0.8-1.0 | 4.5 | |||

| HC3201 | 32.0 | 0.8-1.0 | 1.6 | |||

| HC3202 | 32.0 | 0.8-1.0 | 2.4 | |||

| HC3203 | 32.0 | 0.8-1.0 | 3.2 | |||

| LC1303 | 13.5 | 0.8-1.0 | 3.2 | >3000-4000 |

CBN layer uye Wc-co substrate 2. Zvishoma zvakaderera zveCBN 3. High kupfeka ratio 4. Simba rakanaka rinopesana nekuputika |

metallurgy zvikamu |

| LC1304 | 13.5 | 0.8-1.0 | 4.0 | |||

| LC3201 | 32.0 | 0.8-1.0 | 1.6 | |||

| LC3202 | 32.0 | 0.8-1.0 | 2.4 | |||

| LC3203 | 32.0 | 0.6-0.8 | 3.2 | |||

| HB0903 | 9.55 | 3.18 | 3.18 | > 5000 |

|

|

| HB1204 | 12.7 | 4.76 | 4.76 | |||

| HB1608 | 15.85 | 8.0 | 8.0 | |||

| HB2008 | 20.0 | 8.0 | 8.0 |